Do-it-yourself siding for a private house. Do-it-yourself siding on a wooden house: video instructions, photos, step-by-step installation. Types of additional components

– an excellent material for cladding a house. At its affordable price, it has many positive operational and technical characteristics.

You are offered detailed instructions for installing siding yourself. The guide is universal. Following its provisions, you can complete any finishing that involves installation on a lathing: fiber cement, wood, metal, vinyl, etc.

We install the sheathing

Siding is best attached to pre-installed sheathing. We work in the following order.

The first stage - choosing the material

The frame can be assembled from wooden beams or metal profiles. Metal products are stronger and more durable. In addition, metal sheathing is much easier to attach to an uneven base.

Find out and also familiarize yourself with the calculation algorithm with an emphasis on possible nuances.

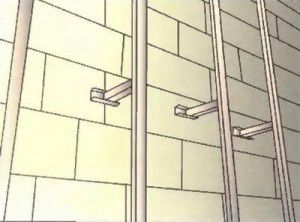

Installation of profiles is carried out in half-meter increments. Hangers are used for wall mounting. This technique will allow you to level out differences in the surface and secure the frame elements at a level.

Wooden sheathing is cheaper. When choosing this option, pay attention to the condition of the wood. It is prohibited to:

- the material has peeled off;

- was deformed;

- had bluish spots and traces of rot, etc.

Elements of wooden sheathing must be impregnated with fire retardant and antiseptic. If the house is built of wooden elements, the walls should also be treated with the listed preparations.

Stage two - preparing the base

The sheathing is easiest to attach to a flat base. First of all, we remove any parts that may interfere. These are all kinds of tiles, bars, platbands, gutters, etc.

The third stage - installing guides

Siding is best mounted horizontally. In this case, we fix the bars or sheathing profiles vertically.

To attach the guides to wooden walls, we use nails or self-tapping screws. If the house is built of concrete blocks or bricks, we fasten it with dowels, having previously drilled holes for them in the wall of the house.

We align each rail by level.

Important! If you plan to do exterior work, it is best to install the siding sheathing after all insulation work has been completed. In this case, there will be two lathing: for insulating materials and for cladding. In this case, the slats of the two frames should be placed parallel to each other.

You can, of course, try to lay insulating layers after attaching the siding sheathing, but this is not very convenient.

Mounting J-profiles

The starting guides must be secured perfectly, because... The quality of the entire cladding depends on the correct installation.

First step. Take a level and find the lowest point on the sheathing. We step back 50 mm from it and put a mark. To do this, screw a little self-tapping screw into the rail.

Second step.

We consistently move around the building and continue to place marks with self-tapping screws to fix the starting profiles. We also screw screws into the corners of the house.

Third step.

We stretch the ropes between the corner marks.

Fourth step. We mark the boundaries of installation of corner profiles on the slats. We take the profile itself, apply it to the corner of the frame structure and put marks along the edges with a pencil.

Important! We leave a 1-centimeter gap between the profiles to compensate for temperature deformations.

Leave a gap between the starting guides and the nail strips.

To avoid making a 6 mm indentation, you can cut off parts of the nail strips so that they do not rest against the J-profile during temperature changes.

Important! Starting profiles must be mounted strictly horizontally! Correct deviations as long as necessary.

If you install guides that deviate from the level, the siding will also warp. It will be extremely difficult to correct this in the future.

Prices for profile mounts

Profile fastenings

We install external corner profiles

First step. We mark the soffits. We need to see where the edges of these elements will be located in the future.

Second step.

If the house is higher than 300 cm, the profiles will need to be placed one on top of the other. To do this, we trim the top profile. As a result, there should be a 9 mm gap between the planks of the joining elements. When laying the elements, maintain an overlap of 2.5 cm.

Important! We join the profiles at the same level on each side of the house.

If the base has a protruding structure, shorten the profile so that there is a 6 mm gap between it and the base.

Helpful advice! Instead of a corner profile, it is allowed to install 2 J-elements (starting). This way you can save money. But this solution also has its drawback - the corner will not be as tight as when using a special corner profile. If you decide to use this method, first glue the wall around a similar corner with a strip of rolled waterproofing material.

Installing internal corner profiles

The procedure for installing these elements does not differ significantly from the technology for arranging external corners - we leave a gap of 3 mm between the profile and the soffit, and lower the lower end of the profile below the J-bar by 0.6 cm.

If there is a protruding plinth or other element from below that stands out from the general level, then between it and the profile we also leave a 6-mm indentation - the profile of the internal corner must not rest against it.

There are 3 methods for arranging internal corners, see the picture.

If the wall height is more than 300 cm, we splice the profiles. The technology is the same as for arranging external corners.

We leave a 9mm gap between the slats, carefully cutting off excess material. The overlap of the upper element on the lower one is 2.5 cm. We install fasteners in 4-centimeter increments, placing them strictly in the center of the holes intended for this. The exception is the highest point. Here the fasteners need to be installed at the top of the hole.

We install frames of openings

For most inexperienced craftsmen, difficulties arise precisely at the stage of framing and doorways. The order of work will vary depending on how the openings are arranged in relation to the plane of the wall.

Openings in the same plane with the facade

In this case, we do the following.

First step. We waterproof openings.

Second step.

We attach platbands or J-profiles to the openings. We equip each opening using 4 platbands: a pair of vertical and a pair of horizontal.

Third step.

The platband at the bottom is connected in exactly the same way, only the bridges will need to be cut and bent on the side elements for their further laying on the profile below.

Openings are recessed into the facade

When installing near-window profiles, we follow the same recommendations as when installing platbands, i.e. We create cuts on the profile corresponding to the depth of the opening, and then bend the bridges and insert them into the finishing elements.

Take the time to understand the principles of bending such bridges. We make them so that they cover the joint of the cladding elements. As a result, moisture will not be able to penetrate inside.

Installing the first panel

We start cladding from the least noticeable wall of the building. This way we can practice and work out all sorts of inaccuracies.

First step. We insert the first cladding panel into the corner profile and into the locking connection of the starting strip.

Important! We leave a 6 mm temperature gap between the first cladding element and the lower part of the corner profile lock.

Second step.

Attach the panel to the sheathing.

It is important to maintain the dimensions of technological indents. If the cladding is carried out in warm weather, we maintain a 6 mm gap; if in cold weather, we increase the gap to 9 mm. When installing panel trims, the indents can be reduced.

Extending panels

We build up the cladding elements with an overlap or using an H-profile.

When attaching panels with an overlap, you must first shorten the locks of the facing panels and the fastening frames so that the resulting overlap has a length of 2.5 cm.

The installation of the H-profile is carried out similarly to the corner elements - at the top we retreat 0.3 cm from the soffit, at the bottom we lower it by 0.6 cm in relation to the starting profile.

Important! We leave a 6mm gap between the H-profile and any obstacles on the house.

Installing the rest of the siding

We continue covering the house with siding. The operating technology is similar to the procedure for attaching the first panel.

Important! Every 2-3 rows we check the horizontality of the cladding using a level.

Having reached the opening, we remove the unnecessary piece of the panel falling on the opening.

We ensure reliable fastening of the panels using “hooks”. For this we need a punch.

We install an additional finishing profile at the bottom of the opening. This will allow the cladding to be leveled.

Installation under the roof

We attach a J-profile under the roof structure.

We work in the following order.

Second step.

We subtract a 1-2 mm indent from the resulting measurement.

Third step.

We mark the whole panel, cut off its upper part with the locking connection.

Fourth step. We create “hooks” in the upper part of the element in 20-centimeter increments. To do this, we make cuts and bend them to the front side.

Fifth step.

We insert the trimmed element into the penultimate siding panel. With a slight upward movement, we snap the inserted element into the locking connection of the finishing profile.

We mount the pediment

We sheathe the pediment around the perimeter. All fasteners, except the top one, are installed in the center of the holes. We install the upper fastening element at the top of the hole. It can be sheathed either with profiles for arranging internal corners or with a starting profile.

The installation procedure is similar to fastening wall panels. We trim the edges of the elements and connect them to the locks of the receiving profiles. We remember the 6 mm indentation when installing in warm weather and 9 mm when doing work in winter.

We fasten the last element of the gable cladding directly through the panel material - this can only be done here.

The cladding is complete.

| Find out how, plus calculations and step-by-step guidance, in our new article. | In order for finishing a house with panels to be as successful as possible, you need to know certain subtleties of performing such work. There is a list of general recommendations for any siding, as well as specific tips for panels made from a specific material. | Now you can perform it yourself at the highest level. | Name (model) |

|---|---|---|---|

| Benefits | Length x width x thickness, mm Quantity per package, pcs. Vinyl Siding "Canada Plus" 1. Coloring in dark colors is performed using the “Cool Color” method (heat absorption), which involves the use of masterbatches. | 2. Excellent appearance remains unchanged even when exposed to high and low temperatures, the range of which ranges from -50°C to +60°C. | 20 |

| 3. Retains shock resistance, even if the ambient temperature drops to -20 to 60°C. | 4. Not susceptible to microbiological corrosion (fungi, mold). 3660 x 230 x 1.1 Acrylic Siding "Canada Plus" Among other useful qualities of Canada Plus acrylic siding, it is worth highlighting: High degree of deformation resistance (perfectly tolerates temperatures up to 75°-80° C). | 2. Excellent appearance remains unchanged even when exposed to high and low temperatures, the range of which ranges from -50°C to +60°C. | 20 |

| "Alta-Siding" – Vinyl Siding | "Alta siding" is: one of the safest finishing materials on the Russian market; frost resistance and the ability to maintain strength even at very low temperatures (from -20 to -60°C); resistance to significant temperature changes and environmental influences; durability: the service life of Alta-siding is up to 30 years; resistance to aggressive substances (detergents can be used to clean siding); non-susceptibility to infection by mold fungi. | 2. Excellent appearance remains unchanged even when exposed to high and low temperatures, the range of which ranges from -50°C to +60°C. | 20 |

| Facade metal siding INSI | INSI siding is made of galvanized steel coated with a layer of polymer composition, which means it inherits all the advantages of this material: resistance to temperature changes (-50°C - +80°C) and mechanical damage; long service life with preservation of original properties (about 50 years); environmental friendliness; non-flammability; Possibility of installation both horizontally and vertically; protection of the building from overheating (in a ventilated facade system); and when choosing one of two new colors (alder or rosewood) - a complete imitation of the appearance. | Length up to 6000, width up to 200, thickness 0.5 | - |

Happy work!

Siding prices

Video - Do-it-yourself siding installation

To give a building a stylish, aesthetic appearance, finishing material such as siding is becoming popular. For its installation, you can, of course, use the services of professional builders. However, the price of construction company services is quite high. Therefore, if you have the right tools, you can install siding yourself. For the owner of a private house or cottage, this is especially true.

The easiest way to have a beautiful front lawn

You've certainly seen the perfect lawn in a movie, on an alley, or perhaps on your neighbor's lawn. Those who have ever tried to grow a green area on their site will no doubt say that this is a huge amount of work. The lawn requires careful planting, care, fertilization, and watering. However, only inexperienced gardeners think this way; professionals have long known about the innovative product - liquid lawn AquaGrazz.

Essential power tools

The process of finishing the facade of any task with siding will be facilitated by the presence of the following tools:

- Hammer.

- Hacksaw and metal scissors

- Cordless drill (screwdriver).

- Construction level (length – 2 m).

- Marker or pencil for marking.

- Roulette, at least 5 meters long.

- Rope.

- Construction corner.

- Electric carry.

- Punch.

Of course, it is not enough to have the necessary tool; you also need to be able to use it correctly. The step-by-step instructions below for covering the facade of a house with siding with your own hands will help you avoid most mistakes. However, before you begin facing work, you should understand what siding is and what materials it is made from.

Siding and its varieties

It is no secret that the quality of any finishing work, including installation of siding, will depend on the material used. Siding is a covering material made in the form of lamellas (plates) or slats. The plates are used to finish the walls and facade of the house, and basement siding is used on the lower floors. This type of facing material is made from raw materials such as:

- Plastic. It is based on polymers made of acrylic and vinyl. The popularity of such material is difficult to overestimate. Despite the low price, it has a number of advantages. Such siding will not rot, because... it is resistant to moisture, it does not crack, it is resistant to fire. Plastic siding can be used both for finishing the house outside and inside. The disadvantage of this material is its low resistance to mechanical damage.

- Metal siding. As a rule, galvanized iron or aluminum is used for manufacturing. This cladding material has maximum resistance to fire and deformation. The disadvantages of metal siding are its weight, and as a result, more labor-intensive installation. In addition, if its polymer coating is damaged, the siding will be susceptible to corrosion. Therefore, covering a log wooden house with metal siding requires special care. The condition of the metal coating should be checked regularly.

- Wood siding. Homes with wood siding on the outside are quite rare. This type of cladding material is not as durable as metal and requires constant maintenance. Wood siding also has a very high price. However, all its shortcomings are offset by excellent thermal insulation, aesthetic appearance, soundproofness, and moisture resistance. Remember that open fire is extremely dangerous for wood siding.

- Fiber cement siding. This material has all of the above advantages. It is absolutely resistant to fire, mold, and moisture. However, it also has a significant weight, so its installation will be difficult. For example, if plastic or metal siding is installed using a tongue-and-groove method, then fiber cement siding is installed only with an overlap and only with the use of special fasteners. Basement siding made from such material is in demand.

Finishing the facade and walls of a house with siding with your own hands is a simple, but very painstaking job. When starting work, calculate the amount of material required. Do not forget that siding is used for the base in the form of slats, and for the walls and facade in the form of panels.

Preliminary calculations. Preparatory work

The approximate amount of siding required for finishing work on a house is determined based on the area of the walls, facade and other elements outside the house. In other words, the area of the walls and facade of the building is divided by the length of the siding panel. An accurate result can be obtained using a sketch of the building. Finishing long wall surfaces with siding will require joining joints; this will require an H-profile. Keep in mind that joints made in different places spoil the appearance of the house. A high-quality sketch of the decoration of the facade of the house allows you to calculate the installation of siding yourself with the least number of connections, while maintaining an acceptable cost.

Before installing siding yourself, it is necessary to carry out preparatory work to prepare the walls outside the house. To do this, you will need to remove dust and dirt, lime and remnants of other finishing materials, etc. from the surfaces to be sheathed. If plaster has been applied to the façade and walls of the house and has become of poor quality, it will need to be dismantled.

In addition, all external elements that interfere with the installation of siding will need to be removed from the walls, these include gutters, cornices, and window sills. For a wooden building, it would be a good idea to check the walls for the presence of fungus and mold.

If you plan to lay thermal insulation materials under the siding, you will need a vapor barrier film. It is used to protect insulation from condensation.

First stage. Frame

Installation of siding is carried out on a pre-prepared frame with your own hands. Metal or wooden materials are used for its manufacture. It is worth noting that metal sheathing has the advantage of durability and strength. In addition, the metal frame is better fixed on uneven surfaces. It is much more difficult to play around with machine defects using a wooden frame.

The profile is attached to the wall using hangers, and the distance between them should not exceed half a meter. This installation method allows you to set the profiles using a building level, despite the unevenness and imperfections of the walls.

If finances are limited or installation of metal sheathing is impractical, use a wooden frame.

For such sheathing, it is prohibited to use material that is flaking, deformed, or has traces of mold or rot. This is especially true for a wooden log house.

The frame is mounted on smooth, prepared walls. Siding panels are mounted horizontally on the facade of the house or its walls. Accordingly, sheathing bars or metal profiles are installed vertically. The guides are attached to the wall of a wooden house using nails or self-tapping screws. If the base is made of concrete, monolith or brick, you should use a hammer drill and dowels. Each rail or profile is set according to its level.

If, along with the cladding work, external thermal insulation of the walls is also planned, the lathing for siding is installed after all work with the insulating material. In this case, two frames will be installed: for siding and for thermal insulation. It is important that the sheathing slats are parallel to each other.

Method of working with siding

Regardless of the material from which the building is constructed, after preliminary work, do-it-yourself siding installation is carried out in the same sequence.

Work on finishing a brick, monolithic, timber, or any house begins with installing the starting panel and fixing it with nails or self-tapping screws. The next step is to install the H-rail, if provided, and install the corner fasteners. Window blocks and doorways are designed using profile J.

Starter profiles and guides must be installed flawlessly, and the step-by-step instructions serve as a guide for novice finishers. The first steps look like this:

- Initially, you need to use a level to find the bottom point on the frame, and, stepping back 5 centimeters from it, make a mark. This is done using a self-tapping screw or nail.

- Consistently, moving around the house, we screw in the screws as marks. Starting profiles will be installed in these places. Do not forget about the marks in the corners of the building.

- We stretch the construction cord between the corner screws.

- We apply the boundaries of the profiles installed at the corners to the frame slats. To do this, we apply the profile to the sheathing, and, using a pencil or marker, apply marks to its edges.

- Adhering to the cord, we make a horizontal gap of six millimeters from the corner profiles and mount the starting guide to the profile or sheathing slats.

Don't forget to leave a gap of 10 millimeters between the profiles.

This is necessary to compensate for temperature differences. A gap of six millimeters should not be made if you remove part of the nail strips in advance, and they will not rest against the J profile when there is a temperature difference. The initial profiles should only be mounted horizontally. Don't save time on this. Otherwise, it will be extremely difficult to correct the subsequent distortion of the siding.

External corner profiles

Do-it-yourself installation of these elements is carried out in the following order:

- We mark the soffits; it is important for us to know where their edges will be.

- We take the guide and apply it to the sheathing; leave a gap of three millimeters between it and the soffit (roof). Then we fix the guide using self-tapping screws, but its lower edge should be six millimeters below the starting profile.

- Checking the vertical installation. If there are no defects, we fasten the bottom and other places. Do not overuse fasteners in corners.

If the height of the building exceeds three meters, the profile will fit one on one. To do this, the top profile will need to be trimmed. This is necessary so that there is a gap of nine millimeters between the connecting elements.

The profiles must be connected at one level and on one side of the building. If basement siding protrudes, the profile needs to be trimmed so that there is a gap of six millimeters between them.

Internal corner profile

The methods for installing internal corner profiles are practically no different from the methods for finishing external corners. The space between the corner and the soffit should be three millimeters, and the lower edge of the profile should be six millimeters below J of the profile. If basement siding or other element protrudes from below, the profile will need to be trimmed.

Finishing window and door openings

Many novice finishers experience difficulties at this stage. The openings can be flush with the wall surface, they can be recessed, or they can protrude. The most common openings are those that are at the same level with the wall. The instructions for finishing such an opening look like this:

- We protect openings from precipitation.

- We install platbands on the openings (for each opening, two vertical and two horizontal ones are used).

- We join the profiles.

Installation of main siding panels

Work on decorating the facade of a house with siding with your own hands always begins with the most inconspicuous part of the building. This allows the installation technology to be developed with minimal losses.

- The panel is mounted in the corner profile and fits into the lock of the starting guide.

- The panel is fixed to the frame.

Subsequently, the panels are mounted using H-profiles or overlap one another. Installation of the remaining panels is no different from fixing the first one. When approaching the opening, the excess will need to be removed. Don't forget to check the horizon of the panels every three levels using a level.

To furnish the lower part of the house, basement siding in the form of slats is used; you should not use ordinary panels for these purposes.

In addition to its decorative functions, siding protects the house from precipitation, winds, and when laying a thermal insulation layer, from temperature changes.

If you want to finish the facade using the dry method, you can use siding, which is suitable for most modern buildings, especially if they are built from sandwich panels or foam concrete.

You can decorate your home with this material yourself without spending a lot of effort. Siding is distinguished not only by the beautiful appearance of the building that it can create, but also by its favorable price.

When considering the complex characteristics of the proposed materials for wall decoration, pay attention to the following factors:

- finishing operating conditions;

- total cost of finishing;

- environmental friendliness.

Information about the characteristics of siding that may be useful for making a decision on covering a house with siding:

- durability;

- subject to temperature deformation;

- resists direct sunlight and adverse external influences;

- impact resistant;

- it is easy to install;

- the finished facade can be easily repaired;

- fire safety.

If you decide to use siding for your home, the first step is to visit a hardware store in person. When buying online, it will be difficult for you to find out the following features:

- uniform color on the outside and inside, indicating the quality of the material;

- quality of mounting holes;

- uniform thickness of panels around the perimeter and among themselves.

Types of finishing material

Siding has excellent technical characteristics. Due to the wide range of colors and textures available, there is a steadily growing demand in the materials market for a house covered with siding.

It is available in the following variations:

- vinyl;

- aluminum;

- basement;

- steel;

- copper;

- cement;

- wood.

Any of the above types is suitable for finishing external walls. Focus on your budget and the desired appearance of the facade. The cheapest will be vinyl (the most popular), the most expensive will be those containing wood or copper. The first two types are usually used to decorate a wooden house with your own hands without much time investment.

Quantity of material

To calculate the amount of base material (panels, hydro-, vapor barrier) you need to measure the area of the facade for finishing minus the area of the windows, plus five percent on top. The amount of profile is equal to the length of the corner lines of the house, including the angles of contact of doors and windows, the perimeter and doubled.

For a rack profile, it is enough to find out the length of the walls from the ground to the beginning of the roof, multiply by the length of the perimeter, divided by 60 cm. To find out the number of additional parts, before covering a wooden house with siding with your own hands, and parts, you need to divide the length of the rack profiles by the distance between fasteners (70 cm). You will need self-tapping screws:

- LN 9 - for galvanized profile, the ability to find out only the approximate quantity.

- TN 25–30 - for wood, to calculate we multiply two by the U-shaped fastening, adding five percent.

What is useful when facing

Typically, covering a house with siding with your own hands requires the following tools:

- screwdriver;

- screwdriver;

- roulette;

- scissors;

- grinder/saw with small teeth;

- hammer;

- level;

- square;

- ladder reaching to the roof.

Before decorating your house with siding, study its complete set, which consists of the following parts:

- starting, corner, finishing, connecting strips;

- elements for slopes;

- drainage;

- soffits.

Let's start the preparatory work

Without preparing the facade for work, you should not start cladding. Remove interfering elements: window shutters, external sills, cornices, window sills, drain pipes. Seal old cracks with mortar or foam. Mold, rot, old paint and peeling plaster should be removed from a house that was built a long time ago.

Afterwards, treat the walls with a fire retardant, an antiseptic for the walls of a wooden house, or a special primer for brick or concrete. Next, you need to carefully examine the facade to understand whether the façade cladding with siding requires an additional frame. It may not be installed only for smooth log walls; in other cases, especially when insulating, its installation is required.

Frame installation

As we just said, in most cases you need a frame: from slats for a log house and from a galvanized profile in the case of concrete or brick walls of the house.

Attention: the slats that are necessary to cover a wooden house with siding, after drying, are treated with the same materials as the wooden house.

So, how to cover the facade of a private building with siding:

- mark lines for a closed contour using a tape measure and level;

- make a mark at the lower point of contact of the wall with the plinth, making a second contour, where in the future we will install the initial strip;

Be careful: if the second circuit deviates from the level indicators, the finishing wall panels may become warped.

- start installation with vertical guides, which are mounted using U-shaped fasteners;

Tip: for a tight installation, you can place pieces of wood or foam underneath them.

- additional guides are made on corner lines, places of future lighting, as well as near door and window openings;

Attention: if you connect the vertical guides to each other, there will be no air circulation, which will expose the façade to destructive biological effects such as fungus or mold.

- lay layers of hydro- and vapor barrier with your own hands;

- Between the sheathing, layers of rolled mineral wool or foam boards are laid, if necessary secured with clamps.

Plinth cladding

If you want to use this material for, use the following instructions:

- install horizontal profiles on the frame;

- attach the starting strips on top;

- measure the supporting parts with a level and an angle;

- fasten the profiles and knees together;

Attention: for secure fastening, use dowel nails up to 8 cm long for this process.

- If you want to end up with a stable base, attach the profiles horizontally.

If this is your first time facing the need to cover a house with such material, and you are not sure how to properly cover a house with siding, study the following material:

- When attaching the panels, maintain a gap of 1 mm between the siding and the screw

Attention: if you forget about the thermal gap when finishing the house, the finishing will soon become covered with cracks due to expansion when heated.

- leave 0.3–0.5 cm of space between the edge and end connections;

Tip: if siding is done in winter, the gap distance is increased due to temporary compression of the material.

- Fasten all screws in the center of the hole, with the exception of one at the top of the pediment, which is driven into the center of the panel itself and the screws of the upper panels.

Without following these simple rules, the technology for covering a house with siding will be incorrect, and the frame will not hold the material well.

Let's start cladding the facade with panels

Step by step, you come to the main point of siding - fastening the main panels, for this:

- use a level to attach the initial profile;

- put panels on it, each of which is attached to the sheathing;

Attention: the mount is done using self-tapping screws in the color of the siding, when choosing which, pay attention to the cap - for strong fastening it must be large and corrugated.

- fasten the panels from the bottom until you reach the gable;

- assemble the cornice, for which notches are applied to the pediment and the starting panel is installed;

- attach the sheathing to the plank;

- use self-tapping screws to mount the cornice.

What to do with openings

To finish the slopes of doors and windows with panels, if present, there are special components that include the following elements:

- slope profiles;

- window aquilons;

- platbands and others.

To cover slopes after repairing windows and doors, you can use two mounting options. Ways to sheathe slopes with siding:

- overlay - it is more reliable for protection against moisture;

- end-to-end - has a more beautiful appearance.

Given the complexity and high cost of implementing the previous options, the technology of siding a wooden house can eliminate them. To do this, frame the frame around the perimeter of the opening with a J-profile. In this case, the siding bypasses the slopes, which are lined separately using a different technology.

Conclusion

Almost always, covering a house with vinyl siding will fully meet your requirements. Despite this, some owners use a log blockhouse to create DIY siding to maintain the look of expensive natural wood. It is very convenient to decorate a house in which the windows are at the level of the walls, without external slopes.

Metal siding is used for commercial properties, where its capabilities provide the benefits of a sheathed structure, which it cannot do for a private home, except that it will complicate the work. If you do not have a strong desire to understand how to cover a house with siding yourself, hire professionals.

The fact is that if you do the finishing yourself, in case of failure there will be no one to blame. In addition, due to inexperience, you risk spending twice as much materials, especially if you are not in the habit of carefully studying the nuances of the cladding process before it begins.

Finishing Siding is a finishing that relates to external work and is intended for any residential buildings and outbuildings. This cladding is also applicable for old houses, because the light weight of the structure is not capable of damaging the foundation.

The popularity of siding has been growing over the years, due to:

- relatively low cost;

- long service life;

- high technical qualities;

- simple care;

- good protective properties;

- large selection of colors and textures.

The big advantage is that you can give any building a modern look with your own hands, saving money on the services of specialists.

Which siding to choose?

Depending on the architectural features of the building and its operating conditions, various types of siding can be used. Materials differ in terms of strength, load on the frame, and care features.

Can be used for finishing buildings aluminum, galvanized And steel sidings. The aluminum type is considered more decorative, as it imitates the structure of wood and lends itself well to painting. This material is not afraid of temperature changes and does not rot. Disadvantages include the ability to deform and the likelihood of corrosion.

- Cement siding produced from high-quality cement with cellulose admixtures. This type of finishing effectively imitates a noble finishing stone. This material is not affected by atmospheric phenomena, does not rot or burn. But siding is heavy, which requires a reinforced frame and complicates its installation.

- Basement siding is a cement or PVC panel that exactly replicates the structure of stone or brick. This material is available in thicknesses of more than 3 mm, as it is installed close to the ground and can be susceptible to moisture and various damage.

Materials and tools

To perform siding installation work you will need tool:

- Scissors cutting metal, grinder, saw.

- Hammer, square

- Screwdriver set, electric screwdriver.

- Construction or laser tape measure.

- Folding ladder.

Today, siding is offered along with components for finishing houses of various configurations. When purchasing, the buyer just needs to indicate the dimensions of the walls, the presence of windows, the type of roof, and the consultant will calculate the required amount of material and cladding elements.

The following are used in this work: components:

- The outer corners cover the ends of the material.

- Internal corners connect the material to each other and to the wall surface.

- The cornice is sheathed with a wind dock and soffits.

- The starting strip is installed around the perimeter of the house, except for doors and gables.

- The J-profile connects extensions, roofs of different levels and hides height differences;

- Window trim and flashings frame the windows.

- The ebb and flow strips are installed around the perimeter of the base.

- The H-profile connects the siding panels to each other if it is necessary to add length.

- Siding.

- Galvanized self-tapping screws are used to install the material; it is better to use self-tapping screws 25-35 mm long, which provides the required gap of 1 mm.

How to cover a house with siding yourself: step-by-step instructions

Carrying out preparatory work

During the preparatory work, they carry out dismantling protruding wall elements, including doors, grilles, platbands. Gaps around door and window openings must be sealed. The surface of the walls must be cleaned, removing dust, dirt, mold, and chipped old finishes.

Installation of sheathing

The panels must be attached to the sheathing. For vinyl profiles are used wooden slats, which must first be treated with antiseptic agents and dried. For metal siding it is better to install a frame made of galvanized profile.

Using a laser tape measure or level, straight lines are marked on the walls until a closed contour is formed. The next contour is drawn below, at the level of the base, measuring the distance in the corners of the walls and finding the minimum value to the base. This location will be installed starting bar. This process is very important, since it determines whether the panels of the entire cladding will not warp.

Vertical bars are attached to the corners of the wall. guides, they are installed using U-shaped elements. These elements must fit snugly against the wall; this can be achieved using wood or foam pads. The guides should be located in increments of 30-40 cm. Near window and door openings, the number of guides is added due to the additional mechanical load. The vertical guides do not need to be connected to each other, this promotes good ventilation.

Insulation and waterproofing

Wooden and aerated concrete buildings must have waterproofing. The insulation is installed at the request of the owner. It is better to give preference to a membrane with moisture and windproof properties. If a decision is made not to use insulation, then the membrane is attached to the surface of the walls, preserving space for ventilation. When using insulation, waterproofing material is installed as the top layer, then a sheathing is installed to provide ventilation space.

Installation of guide elements

Work begins with organizing drainage to the basement. The upper part of the element is located along the intended line. Drainage- This is a rigid element that is easily installed in a level position. Corner profiles are firmly fixed with self-tapping screws in the holes located at the top of the element. The following screws must be screwed into the middle part of the hole.

Door and window openings are framed with J-profiles and window trims. H-profiles for vertical installation are installed using a level. In this case, a gap of 5 mm is provided at the ends to avoid deformation during expansion. Installed in the roof area finish bar.

Panel installation

The panels begin to be installed when all additional elements are installed. The lowest row is secured to the starting bar with a lock at the bottom of the element. The panel is attached using self-tapping screws in the upper part, they are screwed in every 40 cm. All other siding panels are installed in the same way, rising up to the roof with each row. Siding must be movable, so don’t mount it too tightly. A finishing panel is installed at the very top of the structure.

How to cover a house with siding yourself: video

Siding is the best way to quickly update the skin of a building and protect walls from the influence of atmospheric phenomena for many years. If installed correctly and all requirements are met, the service life of this finish is about 30 years.

The process of installing panels is not complicated and understandable even to non-professionals. Just watch the installation video, study the instructions and recommendations, and you can safely get to work.

Evgeniy Sedov

When your hands grow from the right place, life is more fun :)

Content

Upholstery with siding instead of the usual lining is suitable for most types of residential buildings and outbuildings. The lightweight material does not exert significant pressure on the foundation; it is even used for cladding old wooden buildings. This finishing method is distinguished by its affordable price, ease of installation, and durability.

Types of siding

Plates for cladding buildings are made from different materials. Siding can be:

- Aluminum – lightweight metal panels of increased strength.

- Wooden - made from compressed wood fibers. The material needs a protective coating with varnish or paint.

- Vinyl – made from polyvinyl chloride, not subject to cracking, drying out, or rotting.

- Steel is a durable, non-flammable material with various coatings.

- Basement - a type of high-strength vinyl slabs for finishing the lower part of the facade and foundation with stone.

Which siding is best for cladding a house?

Any type of material used for siding has advantages and disadvantages:

- Wooden slabs give the building a presentable appearance, but are expensive and require special care. The material is flammable and susceptible to rotting.

- Metal siding for cladding a house is non-flammable, durable, easy to install and convenient, but can form dents with a strong point impact.

- Popular vinyl planks have all the advantages an owner needs. In addition, this material has a low cost and is used in the installation of ventilated building facades.

Where to order and how much does it cost to cover a house with siding?

Turnkey siding finishing services are offered by construction companies. Sheathing a house with panels involves preliminary installation of a frame structure - sheathing. Depending on the climatic conditions of the area and the purpose of the room, insulation is required. The cost of cladding depends on the type of slabs, finishing area, condition of the walls of the building:

How to cover a house with siding yourself

Wooden houses often need exterior finishing. These may be old buildings that have lost their appearance, or newly erected buildings made of timber or logs. External cladding decorates the facade and eliminates external defects. In addition, the slabs protect the walls from the influence of the external environment and allow the building to be insulated. Self-cladding a house with siding is the simplest, fastest, and relatively inexpensive option for finishing the facade. The choice of material depends on your preferences.

Calculation of required materials and components

Determining the exact amount of finishing material speeds up the installation process. After all the purchases have been made, you can start covering the house without wasting time looking for missing panels. Accurate calculation eliminates unnecessary costs. Siding is slabs with a certain geometric size. To calculate you will need:

- roulette;

- calculator;

- paper;

- pencil.

The number of siding panels is calculated as follows:

- Determine the area of the sheathing. To do this, you need to make a drawing of the house, put all the dimensions on it, and draw the finishing slabs.

- Subtract the area of windows and doorways.

- Add 7-10% for waste for finishing rectangular walls. If it is planned to cover trapezoidal shapes with a balcony, an additional 10-15% is required.

- Divide the resulting value by the usable area of one strip.

Sheathing a house with siding is not complete without fasteners, profiles and slats for proper joining of panels. The components include:

- Start and finish lines. The first element is needed for installing the lower and upper rows of strips.

- External and internal corners, mounted to different surfaces.

- J-profile designed to frame vertical and diagonal cuts.

- Connecting H-profile used for color separation.

- Window strip for finishing windows.

- Platband needed for lining openings.

- F-profile, installed when finishing the cornice and wind panels.

Carrying out preparatory work

Before covering your house with siding, do the following:

- Remove old plaster, especially around door and window openings.

- Replace rotten parts of the walls, nail down loose boards tightly.

- Remove moldings, light fixtures, and water drainage pipes where these elements may interfere with the installation of the slabs.

- Remove climbing plants and tree branches that interfere with finishing work.

- Remove window sills protruding from the walls.

Installation of load-bearing structures under siding

The lathing is attached to the surface of the building. The design simplifies the cladding and smoothes the surface of the walls. The sheathing is:

- Metal. The frame is assembled from ceiling or rack profiles. The metal frame lasts longer and is less susceptible to temperature and moisture.

- Wooden. This method is less expensive. When installing the sheathing, materials left over from construction or repair work can be used. Wood, compared to metal, is more susceptible to moisture or insects and requires special treatment.

Installation of the sheathing begins with marking the wall using a level, tape measure and chalk. The pitch is from 40 to 60 cm. The distance between the brackets depends on climatic conditions, the size of the insulation, the density and weight of the panels. When installing metal sheathing for siding, you don’t have to use a vertical frame; you can attach the consoles directly to the walls. The wooden structure is mounted with self-tapping screws from timber 5x5 cm thick. For massive and thick slabs, it is better to use a size of 5x7.5 cm.

Use of insulation and waterproofing

The insulation under the siding is installed between the struts of the supporting structure. This measure reduces the cost of heating the building. Mineral wool and modern materials based on it are excellent for insulation. The higher the house, the more thorough the insulation layer should be. Recommended density – from 30 kg/sq.m. The material is secured with plastic parachute dowels into which ordinary nails are inserted.

The waterproofing layer creates a barrier to moisture getting under the siding. A special film is placed on the frame with the desired side on top of the insulation. The sheet of waterproofing layer overlaps about 15 cm. To secure the material, staples, mounting buttons or dowels are used. The joints are treated with construction tape. Then the strips are installed. You need to choose elements 3-4 cm thick so that there is space for ventilation between the waterproofing and the slabs.

Sheathing technology

Installation of horizontal siding panels is carried out as follows:

- Attach the starting bar at the bottom.

- Install two or three stripes. The base of the building is covered with plinth slabs.

- Install the outer and inner corners.

- Treat door and window openings.

- Secure the main panels, leaving gaps between the plates and fasteners in case the material expands when exposed to heat.

- Attach the finishing panel to the top of the façade.

In order for the installation process to go smoothly and the building to receive a good external design, it is necessary.

Which side does moss grow on trees?

Which side does moss grow on trees? Bentonite for horizontal directional drilling

Bentonite for horizontal directional drilling Townhouse design: ideas and practical tips Landscaping a townhouse plot

Townhouse design: ideas and practical tips Landscaping a townhouse plot